Recently my dad and I built a custom bookshelf from Australian Red Cedar which was previous used in joinery at St John’s Church Darlinghurst.

For the first half of this year I’ve been running the machining department at my business and haven’t had much time to work on custom or personal pieces, but when dad asked if we could build a piece to present as a gift I was really glad to make time to work on it.

Dad designed the piece, based on the timber we had available, and we then worked together to build the piece, using a mix of machined and hand-cut joinery. Milling and construction of the piece happened over 3-4 evenings, with an additional week for finishing with Livos’ Ardvos Universal Wood Oil, and it will now accompany Matt and Annie on their move and further travels. Repurposing this timber into a piece that has history and meaning for its new owners is always my favourite, and gifting them with something made from timber from the church they were leaving felt very special.

Making pieces like this is joy and pleasure, especially getting to work together with my dad! The below text was written by him.

The bookcase is made from Australian Red Cedar - Toona ciliata. It was made by Liz Duck-Chong and Paul Davies, June 2025, and was presented to Matt and Annie Wilcoxen at their farewell from St John’s Darlinghurst.

Despite it being a light and ‘soft’ wood to work it is an Australian hardwood. It is fast growing tree, that due to its quality and ease of use was almost harvested to extinction during the nineteenth century. First used around 1800, by the 1870s cedar was scarce in NSW. Red cedar is found in buildings, joinery, furniture, railway carriages and almost everywhere that required high quality joinery work.

The timber in the bookcase was first used in St John’s Church Darlinghurst where most of the furniture is made from cedar. The church was built in two main stages with later additions. The original part of the church opened in 1858 and the transepts were added by 1875.

The transept pews, now mostly removed, measure 5.8 metres in length. The three shelves of the bookcase were cut from one pew seat. If you look on the underside of the shelves you will see a rebated channel where the legs of the pews were housed.

The uprights are laminated from a number of smaller sections of cedar recovered from pew ends, a mixture of the 1858 and 1875 builds. You may observe that on the inside face of the uprights are small chamfered edges in the laminating which was part of the edge chamfer on the finished end framing. You may also observe that this timber is darker and redder in colour suggesting it dates from the 1850s.

The back panels are recovered from the pew back panels, also a mixture of 1850s and 1870s timber, that were recessed into timber frames. They have been used retaining some of their damage such as nail holes and splits.

All of the timber has been re-milled to remove the previous finish and surface damage and sections of badly damaged timber have been either cut around or not used.

The shelves and uprights are jointed and glued, there are no other fixings except small nails affixing the rear panels.

Below are some more photos of the process.

|

|

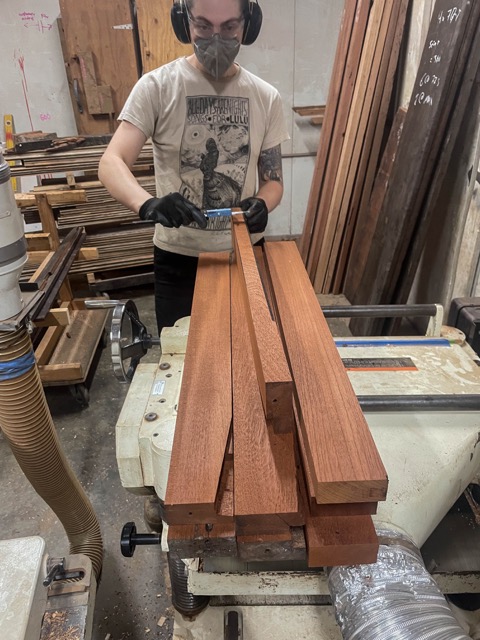

| Milling the uprights before laminating them. You can see small splayed sections where pew backs were set into the uprights | |

|

|

| Pre-assembly, checking all joints are tight and square, the tape is to protect the face timber while the piece is being glued. | Taping up, note that the shelves are over-sized and extend past the uprights, cutting them back and finish sanding takes place after gluing. |

|

|

| Fitting the back pieces before oiling the outside of the case. | The shelves oiled before fitting the back. |

|

|

| Timber for the back panels and the base, cut to size, 2 coats of oil applied. | |

|

|

| Back panels fitted but not oiled on the back face. | Upside down, the base is fitted, you can see the channels on the underside of the shelves. |

|

|

| The back pieces fitted and oiled. | The finished piece in the afternoon light. |

|

|

| The finished piece outside the workshop in late afternoon Australian light. | The farewell lunch and presentation. |

If you enjoyed this post you can get future posts in your inbox at this link.